The following laboratories are available at the Çankaya University Mechanical Engineering Department:

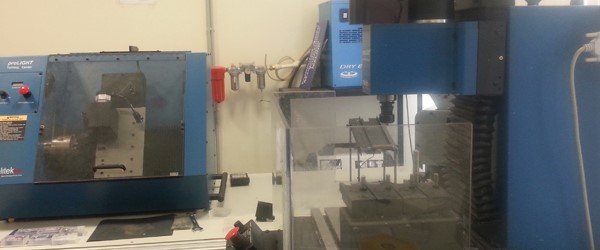

Flexible Manufacturing Systems Laboratory (FMS Lab.) in Çankaya University Mechanical Engineering Department involves an FMS which is composed of a 5-axis industrial robot tending a CNC turning center and machining center. The system is supported by material storage and feeding unit composed of a gravity feeder, pneumatic feeder, and a rack. The system is operated by the OpenCIM software installed on a central computer. In addition, CNC based software installed on two computers, which control the turning and machining centers, enables standalone operation of the machines. The system is used in manufacturing-related courses, where each student produces one part on each machine and learn how to operate the system without human intervention. Additionally, the machining center is utilized in research projects, where precision machining is required.

The Mechanical Engineering Laboratory was established to make the undergraduate students apply the basic measurements related to mechanical engineering. The devices in this laboratory are used within the scope of experiment and measurement course and other related courses. Basic devices in the laboratory are:

The CAD / CAM laboratory was established to enhance the knowledge and skills of students in computer-aided manufacturing. In accordance with the mechanical engineering curriculum, students can practice Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM), which they learn with a software tool, with the CNC milling machine in machine shop. In addition, this laboratory can be used in graduate thesis, masters and doctoral dissertations including machining subjects.

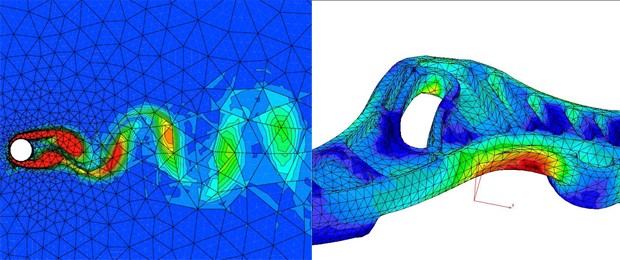

The laboratory contains ANSYS (Finite Elements Analysis Software) and FLUENT (Computational Fluid Dynamics Software) software and 25 high capacity work-stations. For the software there are both education and academic research licenses. This laboratory is used by both undergraduate and graduate students for related courses and research activities.

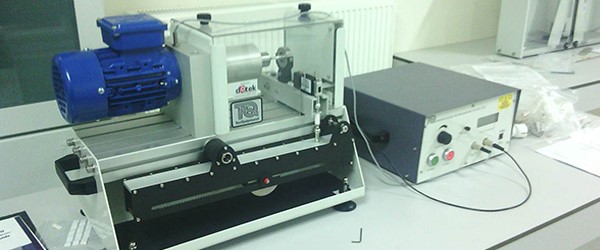

Microfluidic Design and Characterization Laboratory in Çankaya University Mechanical Engineering Department aims to provide an environment for analysis, design, and testing of novel microfluidic devices and structures.

This laboratory is designed for undergraduate students to design and construct experimental systems, and perform experimental measurements in Mechanical and Thermal System Laboratory courses. In the laboratory there are 10 work benches where students can work as a team. Each work bench is equipped with basic measurement devices (power supplier, data logger, pressure gage, thermocouple, Pitot tube, etc.) and hand tools (screw driver, hammer, etc.).

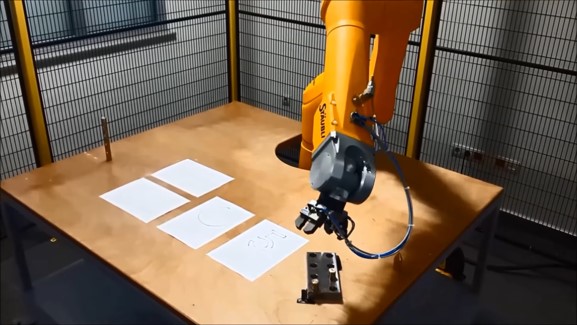

Our students acquire their first experience about robotic control technology in our university by using the robot arm and factory automation devices in our laboratory infrastructure with their own program codes.

The welding laboratory was designed for undergraduate students to practice welding operation within the scope of manufacturing methods courses. The laboratory has an area of 60 m2 and hoods are located next to all welding machines in order to remove the gas in the environment during the welding processes. The welding equipment in the laboratory: